Best Epoxy Glue – Our Top Recommended Epoxy Adhesives

This post may contain affiliate links. We may earn a small commission from purchases made through them, at no additional cost to you.

As we moved away from the industrial revolution, more and more research was done on substances that had the potential to make our lives easier. Some of the substances developed during these times were epoxy, epoxy resins, and epoxy adhesives. Adhesives in particular had a strong impact on the way we live our lives and removed previous limitations in the fields of engineering and woodwork, but what are epoxy glues? Let’s have a look at what these glues do, how they work, and how they can be used.

Table of Contents

What Is Epoxy Glue?

When most of us think of glue, the chances are that your mind drifts to the sticky white substances sold at convenience stores. However, when it comes to DIY and crafting, the role of adhesives takes on a far more significant role. Why? Adhesives in the crafting and engineering industry need to withstand incredible forces ranging from extreme heat and freezing temperatures, to extreme pressure, and general degradation.

This is what makes epoxy glues so cool, they are specially designed to withstand these and many other conditions, and the best part is you don’t have to have one made because they’re available online and in-store for (considering what they’re capable of) ridiculously low prices. How do they work?

Thankfully you don’t need a master’s degree in chemical engineering to use epoxy glues, they’re as easy to use as any other glue and they do a pretty good job, especially the ones that are designed for particular applications. Epoxy glues usually come in two varieties, the two-part epoxy glue, and the single part glue.

What is the difference between the two? Two-part epoxy glue (as the name suggests) uses a two-part mechanism to form the final adhesive, and although this might sound complicated it’s really simple. Upon purchase you will receive one tube of epoxy and one tube of hardener, these are often sold in separate containers or syringes for ease of application.

These can either be combined on their separately and applied to your workpiece or mixed together on the surface you wish to join/repair. Single part epoxy glues come pre-mixed and will start hardening after a specified amount of time once it comes into contact with air. This period of time is known as the pot life of the glue and as it begins to dry you will still be able to adjust your sections.

When working with epoxy always wear safety gear. Why? Well, aside from being really difficult to remove from your hands, fingers, or any other appendage, these adhesives can contain chemicals that can cause serious discomfort if they come into contact with your skin, eyes, or respiratory system. This can be quite intimidating, but it’s worth keeping in mind that these glues only present a potential hazard while they are wet, and once they are completely cured epoxy adhesives are completely inert, 100% food safe, and extremely durable.

What Can Epoxy Adhesive be Used On?

Knowing what epoxy adhesive is as a substance is great, but it isn’t very useful unless you know what it can be used on. Epoxy adhesives are one of the most versatile materials in any industry, so let’s have a look at a few surfaces that they can be used on and the nature of the bond they develop with a given surface.

Wood

If you ever find yourself in a situation where conventional nails and screws simply won’t keep your wooden workpiece together, you can count yourself lucky that epoxy adhesives exist.

Two-part epoxy adhesives in particular have an impressive effect when binding wood workpieces together, showing tremendous tensile strength while being able to withstand forces that would normally be reserved for welded metal.

Two-part epoxy adhesives for wood are readily available and surprisingly affordable, although if you have a larger workpiece, you might be disappointed by the quantities they are sold in.

Brick

If you ever find yourself wondering what the best way to hang your photographs or other furnishings is, your mind might conjure up images of nails and drills and lots of dust everywhere. Fortunately, you can skip all of that and simply get an epoxy glue that has been graded for brick and mortar.

That’s right, there are adhesives out there that are so strong they’re able to support large photo frames, and in some cases entire shelving units if you ever find yourself in the mood or wanting to test the limits of their effectiveness.

Although these adhesives work great when adhering to other materials like brick and/or mortar, we wouldn’t recommend substituting them as a building material and neither would the manufacturers.

Metal

As a species, we have been looking for new, effective, innovative, efficient ways to join metal together since we discovered how to refine and mold it. This is yet another industry where epoxy resin rears its head to offer a cost-effective and durable solution to all of your adhesive needs.

How effective are there adhesives on metal you ask? Well, considering that these adhesives can be found graded for use inside internal combustion engines and high-pressure water pumps, they are pretty good at what they do.

Manufacturers are always looking to make their epoxy adhesives stronger and more durable, even though most entry-level adhesive grades for metals can already withstand temperatures far past boiling point for over 10,000 hours.

Ceramic

Have you ever found yourself looking at a piece of chinaware or your favorite mug that just landed face-first on the floor and wishing more than anything that you could get it back? If you have, then we recommend keeping some epoxy glue around your home, after all, accidents happen, and replacing your favorite kitchenware can be a nightmare.

As we mentioned previously, epoxy resin doesn’t only do a good job of keeping things together, but it is also completely food-safe once it has a chance to cure completely, which means it is great for repairing things that do or might come into contact with foodstuff in the future.

It can be tricky repairing ceramics with epoxy glue due to its inherent slippery surface, but with some patience and preparation, your favorite kitchenware or any other ceramic objects can be good as new!

What Are the Pros and Cons of Epoxy Resin Glue?

Although epoxy resin might be one of the most effective means of sticking things together there are some advantages and disadvantages to using it just like any other product out there. This being said, let’s have a look at some of the pros and cons you’ll have to work with should you consider using epoxy resin glue on your next workpiece.

Pros of Epoxy Resin Glue

Since you’re (presumably) here to learn some more about epoxy resin glue, we’ll start you off with the good news and work our way forward. It should go without saying that epoxy resin glues are one of the most versatile substances on the planet.

One of their key characteristics of epoxy glue is its tensile and shear strength, which can be off the charts in the consumer sector, and if you’re willing to dig into what industrial-strength epoxy glues are able to do, you might find yourself questioning why we ever consider using other bonding mechanisms.

These glues are also highly resilient to extreme heat and cold, which has perpetuated the idea that epoxy glues and epoxy resin, in general, are a sort of “blanket solution” to lots of everyday problems. This might be the case in some sectors, but it isn’t always the best solution.

Although epoxy glue does a good job of being strong, it can also be extremely flexible and even pliable if need be. In fact, you could create an epoxy resin for pretty much any application given enough time and resources, but in some cases, it isn’t very cost-effective, or we’ve simply become accustomed to other forms of adhesion.

Of course, the main draw of epoxy glue is the fact that it will stick to pretty much anything with the exception of certain plastics, or anything that would have a bad reaction with the substance’s inherent chemical composition. Another reason the epoxy resin glue is so popular is that it’s completely food safe once it has been cured completely.

Cons of Epoxy Resin Glue

As we mentioned previously epoxy resin glue is one of the most versatile substances on the planet, but it is by no means a universal tool. One of the few drawbacks that we face with epoxy resin glue is that it takes quite a long time to prepare and cure, and while we’re on the topic of production, you should know that the production of epoxy resin glues and other related products are not particularly good for the environment.

We did mention that epoxy resin is food safe once it has been cured completely, but while in its two-part form the resin and hardener are toxic and will cause serious discomfort if inhaled or ingested. It is for this very reason that you should always wear the appropriate personal protective gear when working with these substances, including but not limited to a face mask, eye protection, and gloves graded for use with resin and hardener.

Once the epoxy has been dried and cured it is chemically inert, but this doesn’t mean that you should behave carelessly when working with or around it. A clear illustration of this rule is when sanding a surface that has epoxy resin glue or a related product on its surface. Cured epoxy dust can create obstructions to your airways and cause serious discomfort.

Finally, raw epoxy resin can cause mild to serious discomfort should it come into direct contact with your skin, and although this is entirely dependent on the individual’s reaction you should always exercise extreme caution when working with any product that contains uncured resin and/or hardener.

- High tensile strength

- Extremely resistant to heat

- Extremely resistant to cold

- Food safe when completely cured

- Versatile

- Easy to use

- Easy to work with

- Readily available

- Contains harmful chemicals

- Can cause discomfort if in contact with skin

- Can cause discomfort if particles are inhaled

- Not food safe when uncured

- Cannot be used on certain plastics

- Quality can vary considerably by manufacturer

- Cannot be handled without personal protective gear

What is the Best Epoxy Glue?

There are hundreds of epoxy glues on the market that offer a wide range of applications in addition to other useful characteristics. How do you know which one is the right fit for you though? We’ve taken it upon ourselves to scour the web in search of the best epoxy glue, and we’ve come up with the top three contenders. These tick all the boxes, featuring durability, tensile strength, versatility, and ease of use.

Best Overall: GORILLA Two-Part Epoxy

If you’re looking for an epoxy you can trust, go ahead and give Gorilla two-part clear epoxy glue a try. What makes gorilla epoxy so great? Gorilla has made a name for itself over the course of the last decade as a household brand, and it should come as no surprise considering how effective and easy to use their range of products are.

Their Two-part epoxy is no different, offering a two-part epoxy glue that is versatile and just perfect for use on virtually any surface you can think of. The Gorilla team has designed this specific epoxy with joining and gap filling in mind, allowing you to easily dispense the epoxy and hardener simultaneously with their two-part syringe applicator.

A great feature of the Gorilla epoxy glue is the fact that it dries completely clear, which saves you some time having to figure out how you’re going to conceal the fix you’ve implemented. This epoxy dries relatively quickly, taking around six to eight minutes to set which gives you more than enough time to make any last-minute adjustments to your workpiece.

This is a useful tool to have around if you ever find yourself in a pinch, but you don’t get an awful lot of glue for the price. Then again, the quality of the adhesive is far above any other in its price range.

- Strong, permanent, fast, and gap-filling; great for multiple surfaces

- For tough repairs needing a durable bond and solvent resistance

- Dries clear and sets within 6 minutes, allowing for repositioning

- Easy-to-use syringe

- Readily available

- Reputable brand

- Dries completely clear

- Strong adhesive bond

- Versatile

- Easy to store

- Reasonable pot life

- Water-resistant

- Sold in small quantities

- Long set time

- Yellows with exposure to sunlight

- Takes 24 hours to cure completely

- Yellows if not stored in ideal conditions

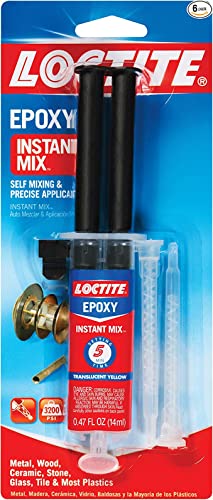

Best Durability: LOCTITE Epoxy Five Minute Instant Mix

Loctite has been around for a really long time; truth be told you might have caught a glimpse of one of their products in your garage or in your dad’s toolbox growing up. This being said, it should come as no surprise that a brand that’s been around as long as the Loctite team has made some really good products.

Loctite specializes in adhesives and has produced a countless number of them over the years, improving their formulas in an effort to create the most user-friendly, versatile, and powerful products adhesives on the face of the planet. In the case of their “five-minute instant epoxy”, they haven’t strayed from this formula one bit.

The Loctite team has made this adhesive with you in mind, it features a dual syringe set up just like the Gorilla glue we covered previously, although this one does seem to be a bit easier to handle in comparison. They have also graded this product for use with tile, ceramic, glass, wood, metal, plastic, and even brick!

This means that no matter what surface you find yourself up against, you’re always going to be prepared. As the name suggests, this epoxy glue sets in around 5 minutes but depending on ambient conditions it can set a lot faster than this. This makes it the perfect tool for all of those time-sensitive projects, a last-minute repair for a broken heel, or for fixing the handle on your favorite coffee mug.

The party piece of Loctite’s five-minute instant epoxy has to be that they have designed the formula to be used with dyes, which pretty much makes it a must-have for any professional crafter or DIY enthusiast out there.

- High-strength non-shrink formula is water and solvent resistant

- Can be mixed with sand, or cement, drilled, sanded, and painted

- Adhesive and filler for wood, metal, tile, ceramic, glass, and plastic

- Easy-to-use dual syringe

- Dries completely clear

- Graded for use with coloring agents

- Can be sanded and molded once cured

- Dries in +/- 5 minutes

- Versatile

- Reasonably priced

- Reputable brand name

- High tensile strength

- Waterproof

- Available in limited quantity

- Cure time is 1 hour

- Cannot be used on vinyl surfaces

Best Value: J-B WELD Original Cold-Weld Steel Reinforced Epoxy

While there are some epoxy resin products out there with a certain degree of pedigree, some are just really good at what they do and don’t need a huge price tag or millions of dollars in marketing to get their piece of the pie.

The truth is, whether you’re a professional crafter, a DIY enthusiast, or just looking for something to fix your door handle at three AM at your local gas station, J-B Weld has (and always will have) your back. It’s truly difficult to think of any of life’s problems that can’t be solved with some J-B weld and some zip ties, and it seems that the J-B weld team has chosen to stick with their formula of being effective and affordable when they designed their cold weld steel reinforced epoxy.

This product can be used on plastics, wood, metal, bring, mortar, even cars, and boats! That’s right, not only is J-B weld waterproof, but it has the tensile strength and longevity to take the punishment of extreme velocities, extreme heat, abrasion, impact, and even extreme cold.

Although the cold weld formula is versatile and strong, it does not come with a dual syringe set-up that many other manufacturers essentially have a standard these days, but on the upside, you will pay a lot less per unit for this resin than you would for others.

As some more silver lining to that dark cloud, J-B Weld is chemical resistant, and can be drilled, sanded, and/or tapped once it has fully cured. As a drawback to this strength and resilience, the cold weld formula takes around four to six hours to set, and a further 24 hours to fully cure, which is considerably longer than any of the other products we’ve looked at so far.

- A welding alternative two-part epoxy system

- Steel reinforced for serious tensile strength

- Easy to use over various applications

- Versatile

- Easy to use

- Reasonably priced

- Extremely strong

- Waterproof

- Heat resistant

- Impact and abrasion-resistant

- Can be sanded, molded, drilled, or tapped

- Not sold with a two-part syringe

- No applicator included

- Long set time

- Long cure time

- Sold in limited volume

How to Use Epoxy Glue

Although it can seem intimidating, using epoxy glue is really easy and can be a fun, easy way to get around those unforeseen mishaps life tends to throw at us. Let’s have a look at how to use epoxy glue effectively so you get the most out of your next purchase.

Prepare Your Workspace

Before you get your hands dirty, don’t get your hands dirty at all. Remember that raw epoxy and raw hardeners are toxic before they have been combined and cured so it’s up to you to protect yourself and your workspace from any potential spillage.

When preparing yourself you should wear some eye protection (any clear goggles or glasses will do), a face mask with a cloth or charcoal filter, and a pair of gloves graded for use with epoxy resin.

Once you have yourself bundled up, protect your workspace by ensuring it is adequately ventilated, and that you have covered up anything you don’t want to get resin on with a tarp, painters’ tape, or some old newspaper.

Prepare Your Workpiece

Epoxy will only work as intended by yourself and the manufacturer if you have prepared your workpiece correctly. How do you do this? This depends on the workpiece in question as different materials tend to have different preparation methods, but the common factor among all of them is that your workpiece should be clear of any dirt, grime, dust, and any other foreign particles before you apply your resin and hardener.

Cleaning your workpiece allows for sufficient surface friction between the adhesive and the surface in question, which means your set and cure time will be incrementally accelerated once it has been applied. As a pro tip, cleaning the sheer metal surface with alcohol and allowing it to dry completely before applying your adhesive is always a good idea.

Apply Your Resin Glue

Now for the easy part, get your workpiece and position it in a way that will allow you to have control of both it and your applicator. Once your workpiece has been positioned, it’s time to prepare your adhesive.

If you don’t have a dual syringe applicator, mix the resin and the hardener in a 1:1 ratio until satisfied. Once these parts have been mixed, you’re working on a schedule, which will be determined by the pot time stated by the manufacturer.

Apply your mixture to the surface of your workpiece, don’t be afraid to be generous with your application, and don’t be afraid to move it around a bit if you have gloves on, although it might be a bit of an effort to clean them later.

Next, apply or join the object in question to your primary workpiece and allow it to set for the manufacturer’s recommended time period. Remember to wipe away any excess with a spare cloth and allow the adhesive to cure before using your workpiece before its intended purpose.

Now that you know what epoxy resin glue is, what the pros and cons of epoxy resin glues are, what the best epoxy resin glues on the market are, and how to apply your resin glues effectively, it’s time for you to get out there and put your newfound knowledge to the rest. Remember to always wear the appropriate personal protective gear and to always work in a well-ventilated area when working with raw epoxy and hardeners.

Frequently Asked Questions

Is Epoxy the Same as Glue?

While epoxy and glue serve the same function, epoxy and conventional glue are quite different. Not only is epoxy strong in both adhesive and tensile strength, but most epoxy adhesives come in two distinct parts. This would be the hardener and the resin which when combined form the adhesive, unlike conventional glues which only come in one part. In addition, epoxy bonds to the surface of a substrate to a far greater degree than conventional adhesives.

Is Epoxy Stronger Than Glue?

Epoxy and glue might serve the same purpose, but when it comes down to it epoxy is used for more “heavy-duty” purposes and thus has been designed with superior tensile strength and durability. This is the case with most epoxies, but there are some extremely powerful conventional glue products out there.

Is Epoxy Waterproof?

One of the many cool parts of using epoxy adhesives and even epoxy resins is that they are either water-resistant or completely waterproof. This is an inherent result of using the two-part epoxy and hardener design which makes epoxy adhesives one of the most versatile ways to bond surfaces together.