Food-Safe Wood Finish – Choosing the Best Varnish for Wood

This post may contain affiliate links. We may earn a small commission from purchases made through them, at no additional cost to you.

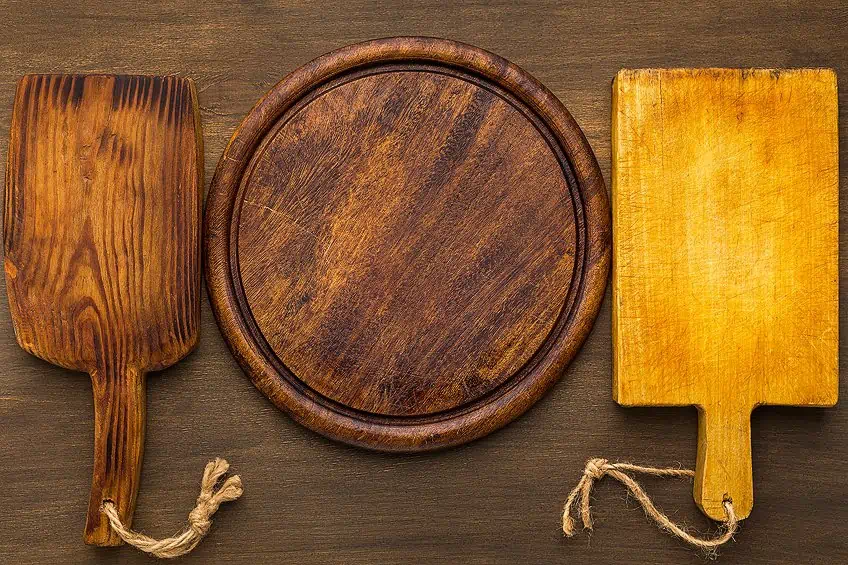

You may be thinking about refinishing an old wooden chopping board, or perhaps a set of wooden bowls, but many of the finishes available have toxic ingredients and chemicals that could harm one’s health if ingested. Thus, when finishing wooden items that are likely to come into contact with food or your mouth, you will need to ensure that the varnish you select is food safe. There are a variety of food-grade clear coats available on the market, and this article will explore all that is on offer to help you make an informed decision about the best food-grade varnish for your wooden surface.

Table of Contents

- 1 Are All Wood Finish Products Food Safe?

- 2 Different Food-Safe Wood Finishes

- 3 Selecting a Food-Safe Wood Finish

- 4 Applying a Food-Safe Wood Finish

- 5 Frequently Asked Questions

- 5.1 How Do You Apply Food-Safe Lacquer?

- 5.2 Do Oil Finishes Leave a Greasy Residue?

- 5.3 Can You Apply a Varnish Over a Wax Finish?

- 5.4 What Are the Benefits of Applying an Oil-Based Finish?

- 5.5 What Are the Advantages of Using a Wax Product?

- 5.6 Can Oil Be Applied Over a Coat of Varnish?

- 5.7 What Is the Difference Between Lacquer and Varnish?

- 5.8 Are Oil Finishes Like Tung Oil Food Safe?

- 5.9 What Are the Benefits of Using a Varnish?

- 5.10 What Do I Do if I Apply Too Much Oil?

Are All Wood Finish Products Food Safe?

Sadly, not all wood finish products are made to the same level of quality, and some brands may not live up to their claims of the product’s purity. In fact, many commercially produced products available on the market contain metal compounds, thinners, solvents, and dryers, to list but a few. Thus, you must ensure that you always consult the label carefully so as to guarantee that you are purchasing a wood finish that is truly food-safe. Also, follow the instructions when applying the product, and ensure that any rags are disposed of correctly when you have finished.

This might all sound a little scary and overwhelming, but we will help you by looking at a few of the things you need to consider when wanting to refinish your wooden items. You will then be able to decide if your wooden pieces will require a food-safe wood finish or not.

Wood Projects That Require a Food-Grade Wood Finish

If you are doing a project that involves wood, you will need to know how to finish it. This is to ensure that it is preserved for years to come and that the look is finished off correctly. Of course, raw wood can look stunning, but unfortunately, it will not last long and can be hazardous in the home. Examples of projects that require a food-grade varnish include:

- Toys

- Tables

- Cutting boards

- Shelves

- Bowls

- Butcher’s blocks

- Benches

- Cutlery

- Chairs

- Plates

Different Food-Safe Wood Finishes

Before you can begin tackling your wood projects, you will need to select the best food-safe clear coat for your particular piece. We have put together the details of the most common wood finishes that are also food safe.

Shellac Finish

To protect wooden surfaces from moisture, you will need to seal them, and you can do this with a shellac product. Shellac comes from the Lac bug and is completely natural – it can even be formulated for use in coating candy and sweets! This type of finish will provide a glossy protective film over the surface of the wood.

Suggested Product: RUST-OLEUM Zinsser Bull’s Eye Clear Shellac Spray

This product by the renowned Rust-Oleum brand is an excellent option for sealing and preserving your wooden items. The solution itself has an alcohol base that has been combined with pure lac, which is a naturally secreted resin from the Lac insect found in India. You have a choice between a clear or amber finish, both of which will make your wood look soft and natural. This product is fast-drying, easy to use and maintain, and will enhance the natural appearance of your wooden piece.

- An all-Natural, non-toxic, and easy-to-use classic shellac finish

- An alcohol-based solution of pure lac, a naturally secreted resin

- Clear or amber shellac finish appears soft and natural

PROS

- Completely natural and non-toxic

- Simple-to-use spray format

- Dries quickly

- Fairly easy to clean

CONS

- Strong odor

Oil Finish

Oil finishes include walnut oil, tung oil, linseed oil, mineral oil, and coconut oil. These have either a non-drying or drying finish, and it is important to select the correct product to suit your requirements. Drying oils are more durable as they become thicker and harden once exposed to air. Non-drying oils, on the other hand, do not harden nearly as much and will maintain much of their liquid format.

Pure Tung Oil

This is a well-known drying oil that originates from China and has been used for hundreds of years. The seeds of the tung tree are used to make the oil and can be used to harden wooden items and even waterproof boats. Thanks to the oil being completely natural, it is food safe. Tung oil is simple to use and is an environmentally friendly product. The oil protects the wood from daily wear and tear, water, alcohol, and oils. Additionally, it penetrates the wooden surface much deeper than other food-grade wood sealers. This oil is more durable and longer-lasting than shellac but takes much longer to dry.

Suggested Product: HOPE’S 100% Pure Tung Oil

Hope’s tung oil is well-known among fellow woodworkers as a product that will deliver the best hand-rubbed finish over your wooden surfaces. Simple to apply by wiping it on, this oil permeates deep into the fibers of the wood, becoming one with the wood as it cures. Once dry, you will have a durable film on top of your wooden surface that is able to resist water, oils, alcohol, and general wear and tear. Apply this oil to any of your wooden surfaces in order to achieve a beautiful finish that provides long-lasting protection.

- A natural oil recognized by craftsmen for providing stunning finishes

- Penetrates deep into the wood fibers and cures to a flexible solid

- Resistant to moisture, alcohol, oil, providing lasting protection

PROS

- Easy to use

- Penetrates deep below the wood’s surface

- Offers lasting protection and is resistant to moisture, oils, alcohol, and everyday wear and tear

- Works on all kinds of wood

CONS

- Application process takes a long time

- Can give off a strong odor

Food-Grade Mineral Oil

This is unlike the other products mentioned, as this oil does not dry and will therefore need to be regularly applied to ensure that the wood is protected from any damage. Mineral oil is great for use on items like cutting boards and countertops and will leave you with a stunning finish. As a non-toxic product, this type of oil is odorless.

Popular Product: ULTRA PRO Food Grade Mineral Oil

This mineral oil offers excellent value for money in that it is a food-safe white oil that can be used in almost all industries. This is the ideal oil for treating kitchen pieces like cutting boards and butcher’s blocks, as well as protecting machines used for processing food and sealing stainless steel kitchenware. The oil is completely non-toxic, odorless, tasteless, and colorless, making it ideal for pieces that will come into contact with food. This product is perfect for rehydrating your wood without leaving any oily residue on its surface.

- A non-toxic, non-drying product derived from refined petroleum

- Oily characteristics make it ideal for smoothing and softening

- A wide variety of applications for personal and industrial uses

PROS

- Does not leave an oily residue

- Non-toxic and odorless

- Easy to use

- Conditions wood, preventing drying and cracking

CONS

- Requires monthly reapplication

Walnut Oil

Once cured properly, walnut oil will protect your wood from alcohol and water as a food-grade varnish. If you do not allow it to cure, the wood will go rancid over time. As this is a nut-based product, those with nut allergies should exercise caution when using it.

Popular Product: MAHONEY’S FINE FINISHES Ultimate Walnut Oil

This walnut oil by Mahoney’s Fine Finishes is perfect for protecting your kitchenware while providing a beautiful satin shine. The product is completely food-safe and is a great option for all kinds of wooden pieces, from furniture to musical instruments. You can expect protection from spills, abrasions, and scratches when you apply this oil to your wooden surfaces. It is simple to use, quick to dry, and offers a high level of control thanks to its clever nozzle design. This is the perfect product for deeply penetrating your wood for lasting beauty and protection.

- This walnut finish oil provides excellent protection and a satin finish

- Penetrates the wood pores deeply and is quick to dry

- Easy to use with a walnut scent and no toxic residues at all

PROS

- Dries quickly

- Can be applied with ease

- Comes equipped with a nozzle, which makes application simpler

- Multi-purpose and can be used on a variety of wooden surfaces

- Effectively absorbed deep into the wood and leaves a satin finish

CONS

- Dries more slowly than advertised

- Not very durable

Raw Linseed Oil

This oil is made from flax seeds and does not need any refinements. It offers your wooden surfaces protection from the sun and water, making it perfect for wooden items that will be stored outside. However, this particular product can take months to dry, during which time you will need to take particularly good care of your wooden piece.

Suggested Product: SUNNYSIDE CORPORATION Pure Raw Linseed Oil

This linseed oil by the Sunnyside Corporation is an excellent choice for providing a quality protective finish over your wooden pieces. The oil burrows deep into the wood to allow for the utmost protection and will increase the piece’s resistance to water and weather. This oil can be applied to raw wood or directly over an oil-based paint or stain, and will take up to four days to cure properly.

- Penetrates deeply and protects the wood with a quality finish

- Increases water repellency and weather resistance

- Can be added directly to oil-based paints and stains on raw wood

PROS

- Easy to use

- Penetrates the wood deeply

- Provides protection from the sun and water

- Low odor

CONS

- Can only be applied to raw wood

- Takes a long time to dry

Coconut Oil

This is the last food-grade sealer on our list and it is ideal for use on cutting boards and butcher’s blocks, you will need to ensure you are using the correct version of the product. To stop it from going off it needs to be distilled or fractionated.

Suggested Product: CLARK’S Chopping Board Coconut Oil and Wax

Clark’s coconut oil is a refined plant-based finish that moisturizes and revitalizes your wooden pieces, preventing the wood from splitting, cracking, or drying out. The oil works by penetrating deeply into the wood’s fibers, leaving behind an attractive food-safe finish. As this is a non-drying oil, you will need to reapply it every few weeks in order for maintenance.

- A plant-based oil with no extra additives or preservatives

- Oil penetrates wood deeply, working its way deep into the wood grain

- Reapply the oil monthly to prevent drying, cracking, or splitting

PROS

- Easy to use

- Additive- and preservative-free

- Safe for human consumption

- Provides stunning results

- Preventa drying and cracking

- Excellent value for money

CONS

- Has to be reapplied every few weeks

Wax Finish

Wax products provide you with a stunning finish and are simple to use. They are perfect for chopping boards and butcher’s blocks and can be removed with ease. However, you will have to look after the wood and reapply the wax when necessary.

Food-Grade Beeswax

These products are made from beeswax. The honeycomb is refined and can be used to produce gel capsules, glaze fruit, and create chewing gum. Beeswax is a non-toxic product that can be used on the majority of food surfaces. You will have to keep the product in a cool area, however, as the wax will melt in the heat, which can be a problem if you are not careful.

Suggested Product: Howard Products Butcher Block Conditioner

This is a top-rated wax condition for wooden cutting boards and other kitchen-related pieces. This Conditioner is a 12 fl oz solution designed to maintain and protect wooden kitchen items. Made with food-grade mineral oil and natural waxes, it ensures safety for all food-preparation surfaces. The conditioner penetrates deeply into the wood, preventing drying, cracking, and moisture damage, while also revitalizing and enhancing the natural beauty and color of butcher blocks, cutting boards, and other wooden utensils. This blend of oil and waxes provides a comprehensive care solution, keeping your wooden kitchen tools in top condition.

- Made with food-grade mineral oil and natural waxes, ensuring it is safe for all wooden food-preparation surfaces

- This conditioner penetrates deeply into the wood, providing excellent protection against drying, cracking, and moisture damage

- The blend of mineral oil and natural waxes revitalizes and enhances the natural beauty and color of wooden kitchen items

PROS

- Food-Grade Safe

- Deep Moisturization

- Enhances Appearance

- Easy Application

- Protective Layer

CONS

- Frequent Reapplication Needed

- Greasy Residue

- Absorption Time

Carnauba Wax

This is also referred to as Brazil wax or palm wax, and is a plant-based product that is food safe and provides a non-toxic clear coat. When added to beeswax, you will have a durable finish that is also water-resistant. This type of wax is well known for its stunning finish and shiny appearance.

Recommended Product: WALRUS OIL Carnauba Wax Flakes

This is an extremely hard wax, which means that while it will provide excellent protection, it is also quite tough to apply. The wax is ideal for larger projects as it generally needs to be applied with a buffing machine or by melting it, as it is too hard to apply by hand. You will be left with a stunningly shiny protective finish.

- FDA-approved, ensuring they are safe for use on food-contact surfaces and skin applications

- These wax flakes can be used in a variety of projects, including making food-safe finishes for cutting boards, creating homemade cosmetics, and crafting natural polishes

- It contains high-quality, pure carnauba wax flakes, known for their durability and superior finish

PROS

- Food-Safe and Skin-Safe

- Versatile Applications

- High-Quality

- Natural Product

- Easy to Use

CONS

- Melting Required

- Cost

- Specific Use Cases

- Hardens, so difficult to apply

Paraffin Wax

Paraffin wax is made from petroleum and is regularly used in the process of making preservatives such as jams, which means that it is safe to eat. You will have to apply this wax monthly, however, as it does not dry. So, maintenance will be required to ensure that you are protecting the wood properly.

Suggested Product: RED HEAD BARRELS Oak Barrel Sealing Wax

This paraffin wax is available in a very small quantity, making it ideal for waterproofing and sealing leaks. In fact, this wax product was formulated specifically for sealing old oak barrels. The wax is non-toxic and will not impact the flavor of the liquid inside the barrel.

- 1/3 ounce of unscented unflavored barrel wax for sealing leaks

- Perfect consistency for sealing oak barrels - not too soft or hard

- Does not change the flavor of your oak barrel contents

PROS

- Great for waterproofing

- Non-toxic

- Wax will not impact the favor of any liquids it is in contact with

- Easy to use

CONS

- Requires reapplication monthly

- Very small quantity

Polyurethane Finish

This finish can be purchased with either a water or oil base, and is often described as liquid plastic. The water-based version tends to be more popular due to it having very little odor, how fast it dries, and its low toxicity levels. However, water-based polyurethane is a lot less durable than its oil-based counterpart. Indeed, oil-based polyurethane offers a lasting protective finish, but it releases more hazardous fumes and emits a strong odor. It also dries more slowly. It can be quite difficult to find a food-safe polyurethane option, but once dry, most polyurethane varnishes should become food safe.

Suggested Product: MINWAX Water-Based Polycrylic Protective Finish

This water-based polyurethane product provides a fast-drying, crystal-clear finish that makes it perfectly suited for woods of a lighter color, such as maple and birch. The formula has a water base, which means that it is easy to clean up and will emit only a low odor. Expect a beautifully transparent finish that will not yellow and that is available in a variety of sheens.

- Protects and adds beauty to most interior wood surfaces

- Crystal-clear finish is ideal for use over light-colored woods

- Available in gloss, semi-gloss, satin, matte and ultra-flat finishes

PROS

- Very durable

- Non-yellowing

- Minimal odor

- Crystal-clear when dried

- Dries quickly

- Easy to clean

CONS

- Small quantity

- Not waterproof

Lacquer Finish

Lacquer will provide you with an Asian-inspired finish that is intensely glossy. This type of finish tends to discolor over time, however. While quite durable, lacquer finishes are unfortunately prone to scratches. Their thin consistency means that they need to be applied by using a sprayer, which in turn means that you must work in a well-ventilated area to encourage airflow. Lacquers (also referred to as varnishes) are some of the simplest products when having to finish your wooden items. Sadly, a lot of these products have hazardous substances in them, making it difficult to find a food-safe version.

Suggested Product: DEFT Clear Wood Finish Lacquer

This clear finish dries in less than 30 minutes and has great anti-yellowing properties. The lacquer will not leave any brush marks and will provide a semi-gloss sheen. The final finish, once cured, will be resistant to water, juice, and alcohol.

- Clear finish that will not yellow over time

- Dries quickly within 30 minutes and leaves no brush marks

- Semi-gloss finish is resistant to alcohol, fruit juice, and water

PROS

- Easy to apply

- Has anti-yellowing properties

- Resistant to juice, alcohol, and water

- Does not leave brush marks

- No sanding required in-between coats

CONS

- Has a thick consistency, so you have to thin it before applying (or brush it on)

Varnish Finish

This term refers to most wood finishes that can be used on raw wood and are durable and weather-resistant. A varnish protects your wooden surface from UV rays as well as water, making it ideal for use on decks, boats, and beach chairs.

Suggested Product: TRIED & TRUE Varnish Oil

This top-rated varnish oil is formulated with linseed oil and natural pine resin to provide you with a premium finish for all of your interior wooden items. You will be left with an eye-catching semi-gloss shine over your surface, where both gloss and durability are increased with each additional coat. This brand boasts that their hand-rubbed varnish will only get more durable with time, making it ideal for protecting your pieces from scratches and abrasions.

- A superior penetrating linseed oil and natural pine resin finish

- A fine furniture finish with a high resin content and semi-gloss sheen

- Ideal for high-quality, interior furniture, tables, and countertops

PROS

- Penetrates the surface

- Provides long-lasting durability

- Produces an attractive sheen

- Offers scratch and abrasion resistance

- Safe and easy to use

CONS

- Long curing time

A Summary of the Different Food-Safe Wood Finishes

| Type of Finish | Advantages | Disadvantages |

| Shellac |

|

|

| Oil |

|

|

| Wax |

|

|

| Polyurethane |

|

|

| Lacquer / Varnish |

|

|

Selecting a Food-Safe Wood Finish

With so many options on the market, it can be overwhelming to pick the option that is best for your project. The initial aspect to take into consideration is whether you require the oil to penetrate the wood or if you simply wish to seal the surface of the wood.

It is easy to apply penetrating oils as they simply soak into the wood, although they provide less protection. On the other hand, surface sealers (film finishes) remain on the surface, giving a protective layer. It can be harder to apply surface sealers, but the result makes it worth it.

When you have a wooden item that is used regularly and is exposed to daily wear and tear, we suggest using a surface sealer. Penetrating oils are perfect for items that do not require much protection, such as bookshelves and picture frames.

Not all surface sealers are food safe, but the options we have provided in this article are non-toxic surface sealers including polyurethane, waxes, lacquer, shellac, and varnish.

If you decide to use a penetrating oil, you will need to decide on whether you want an option that needs to be reapplied or one that only requires a once-off application. This can be decided by going either with a non-drying or drying wood finish.

Usually, you will be able to achieve a solid protective layer when your penetrating oils cure, but it will not be as strong or solid as that of a surface sealer. When the oil comes into contact with oxygen, it hardens as a result of the process called polymerization, which means that as soon as it touches the wood it will start to cure.

Non-drying treatments or oils stay wet as the oil does not cure, and over time these will wash away. The wood will leave a residue on anything that touches it, so be sure to use a flavorless, odorless option if possible. You will need to reapply the oil regularly in order to ensure that the wood stays “wet”.

Drying oils include walnut, linseed, and tung oils, while non-drying oils include coconut and mineral oil.

How Safe Are Food-Safe Wood Finishes?

In today’s society, where people are so health-conscious, most wood finish brands have removed any toxic ingredients such as lead dryers. You do not have to avoid any particular wood finishes, just ensure that you consult the product label carefully before taking your chosen wood finish and applying it.

Most surface sealers offer you the benefits of drying quickly, lasting long, and offering the best protection whilst still being food safe. You should try to avoid surface sealers that include polyurethane, lacquer, Danish oil, linseed oil, varnish, and even paint.

There is much debate over whether or not polyurethane can truly be food safe. The debate arises in terms of whether most wood finishes are in fact food safe when they have completely cured. Curing is more than just being dry to the touch; the odor needs to dissipate as well. Most recommendations suggest waiting 30 days to ensure that the finish has completely cured.

There is minimal research that supports the thought that wood varnishes are toxic when accidentally eaten by a person. Even food-safe wood sealers contain dryers or solvents that assist with speeding up the drying time. When your wood finish has completely cured, there should no longer be a toxicity threat. However, you should still always consult the product label beforehand to ensure your safety.

The products we have listed above are food-safe wood finishes, so if you want some peace of mind, we suggest that you select one of those options in order to ensure the safety of you and your family.

Applying a Food-Safe Wood Finish

We will now look at how to apply your food-safe wood finish to your wooden item, with a focus on applying an oil finish. The same methods can be used for both non-drying and drying oil options. Keep in mind that any rags you use to apply the oil finish have to be disposed of properly when you have finished.

Applying an Oil Finish

- You will have to use a lint-free cloth and wear nitrile gloves so that your hands are protected.

- You can apply the oil either by dipping the rag into the can or by choosing to pour the oil straight onto the wood.

- Spread out the oil with your rag, ensuring that you work with the grain.

- Allow the oil roughly 10 minutes to sit and saturate the wood before wiping any excess away.

- The first layer has to have dried completely before you can apply the next layer.

- To achieve a smoother finish, you can use sandpaper to sand the wood before it dries. Use your rag to wipe away any excess dust and then allow it to dry before applying another layer of oil.

This is a very basic guideline to apply penetrating oils. You will still need to read the label of the product before you use it and make sure that you have everything you will need to finish the project off properly.

Discarding Oil Finish Rags

As mentioned, it is imperative that any rags you have used be disposed of properly. This is because the penetrating oils, once they have been exposed to oxygen and dried, will have soaked the rags. The curing process of an oil generates heat, which when applied to wood in a thin layer will not make a difference, but when saturating the rag can build up the heat even more.

Thus, simply throwing your rags away in the bin can result in their bursting into flames through spontaneous combustion. In certain situations, you might hear an explosion that will bring attention to the danger, but this is not always so, and you may not even notice until it is too late.

The proper way to handle and dispose of your oil-soaked rags is to open them up and hang them over a bucket. Allow one or two days for the rag to dry before throwing it in the trash, after which time it should not spontaneously combust.

How to Apply a Surface Sealer

The most popular surface sealer is shellac, which is a natural food-safe wood finish that can be used on a variety of surfaces. You can use shellac for the majority of sealing jobs, but you are not able to use it with non-grain-raising stains, food-safe polyurethane, or water.

When using a food-safe polyurethane finish, you must ensure that you consult the label beforehand to see whether or not sanding is required. To properly protect and care for the wood, you will normally have to apply an additional conditioning treatment and sealer. When applying a food-grade sealer, consider the following tips:

- Always paint in the same direction of the grain of the wood using a clean brush.

- Apply the surface sealer evenly, although you will probably have to apply more to the end grain than to the rest of the wood.

- Allow at least two hours for the sealer to dry, and then sand gently, being careful not to damage the newly sealed surface.

- Any excess debris and dust need to be wiped off, and then you can apply a final coat if necessary.

- Porous wood will require several coats in order to be properly protected and have sufficient coverage.

If you are creating a wooden object that will be used for presenting or preparing food, then the finish must be food-safe. Our above guide should assist you in selecting the correct product for your wooden item. Enjoy!

View our Food Safe Clear Coating web story here.

Frequently Asked Questions

How Do You Apply Food-Safe Lacquer?

Lacquer is simple to apply and can be used in tight, small spaces while having a low odor. Despite the odor being minimal we, still suggest that you varnish the wood in a well-ventilated area or work outside. Simply begin with applying the first coat thinly and allow it to dry completely before you begin applying a second coat.

Do Oil Finishes Leave a Greasy Residue?

Oil is used to penetrate the surface of the wood and in doing so, moisturizes the wood. You can buy oils in either non-drying or drying options, but the residue is minimal. You will, however, be left with a lot of residue if you apply too much oil.

Can You Apply a Varnish Over a Wax Finish?

No, it is not possible to apply another product on top of a wax finish, as the wax will stop the varnish from adhering to the wood. Oils and varnishes are meant to penetrate the wood and the wax layer will stop this from happening. You will have to remove the wax before applying any new products to the surface of the wood.

What Are the Benefits of Applying an Oil-Based Finish?

Oil-based finishes preserve and protect through penetrating deeply into the wood. They are simple to repair and maintain and if you apply too much by mistake, you can just wipe it off.

What Are the Advantages of Using a Wax Product?

By using a wax finish, you will achieve a premium look for your wood items. You can re-wax as often as you want in order to ensure that the glossy sheen is maintained.

Can Oil Be Applied Over a Coat of Varnish?

No, as the varnish creates a film over the wood that stops the oil from being able to penetrate the wood. You will first have to remove the varnish if you wish to apply an oil finish.

What Is the Difference Between Lacquer and Varnish?

Most people prefer to use varnishes as they are safe to use and simple to apply in the home, whereas lacquers contain solvents and are used by professionals. At the end of the day, however, they are pretty much the same thing.

Are Oil Finishes Like Tung Oil Food Safe?

The majority of wood oils have been formulated for use on wooden products or food surfaces that come into contact with food. Ensure that you consult the label before using the product to guarantee that it is in fact food safe.

What Are the Benefits of Using a Varnish?

Varnishes are easy to clean, tough, durable, and are an ideal option for use on your wood projects.

What Do I Do if I Apply Too Much Oil?

It is pretty simple to fix: Simply take a lint-free cloth and wet it using thinners or white spirits, and then wipe away any excess oil. Try not to use too much of the spirits so as to ensure that you do not damage the wood in any way. This is one of the main benefits of using an oil-based finish.