E6000 Glue Review and Guide – Best Industrial Strength Craft Adhesive

This post may contain affiliate links. We may earn a small commission from purchases made through them, at no additional cost to you.

There is nothing worse than when your child’s Mother’s and Father’s Day gifts take a tumble and smash on the floor. Especially when the gifts are those “World’s Greatest Mom” or “Dad of the Year” mugs that are ever so cheesy, but you hate to see broken because it was a gift from your child. Quickly, fix it before they come home from school! Hopefully, they won’t notice, or if they do, at least they can appreciate the fact that you fixed it. Today’s topic is an E6000 glue review and a guide on how to use it. We will talk about the miracle repair solution that is E6000 glue and its uses. We will discuss whether or not E6000 is food safe, and how strong it is. We will also discuss how to use E6000, inclusive of the E6000 dry time as well as the E6000 set time. Lastly, we shall include a comparison of glues, so get ready to learn the differences between E6000 vs. super glue.

Table of Contents

E6000 Glue Explained

The uses for E6000 glue are seemingly limitless. Not only is it extremely versatile, but it also works on a variety of surfaces and materials. If you swear by E6000, then you are not alone, because almost every person in the DIY trade and even industrial sectors have been raving about this product, as is evidenced by the countless E6000 glue reviews that you can find all over the internet. If this is your first encounter with this product, then keep reading this E6000 glue review and guide.

E6000 is, it has been dubbed one of the toughest glues available, with a bond strength like few others. In addition, multiple reviews confirm that the drying time for E6000 is indeed super quick, making this the most desirable of combinations: a strong glue that is seriously fast-acting. The same goes for the set time. No pressing of parts together for what feels like an eternity. And as far as possible applications are concerned, you will struggle to find a project that the glue will not work for. From photo frame repairs, that precious mug, and even attaching decorative pieces straight onto your walls, this glue does it all.

Another benefit is that E6000 dries transparent. That means it will not ruin the appearance of whatever you are repairing, so maybe your children might not even notice that their mug gift accidentally smashed. It is also great for indoor and outdoor repairs, because it can withstand several damaging factors, like liquid spills, humidity, rain, or intense UV rays.

Uses for E6000

Now that you have a rough idea of what E6000 adhesive is, and just how strong it is, we can start discussing how and for which purposes E6000 can be used. Do not let the intense strength of E6000 glue fool you into thinking that it is only meant for professional applications, because this glue is ideal for even the most basic tasks. Are you an avid crafter? Do you love customizing your own bead, and other odds and ends? This glue could be a favorite of yours and we strongly suggest you give E6000 a try.

As noted above, a major plus of E6000 as that it dries transparent., so the aesthetic of your mug will survive the fix without those dreaded crack-marks filled with yellow glue. In addition, the E6000 cure time only takes a couple of hours, so you will be able to pour yourself a fresh cup of coffee before you know it.

Another advantage of this glue is that once cured, it is impenetrable to liquids. As E6000 is not soluble, it can withstand the heaviest rainfall or complete immersion in water. You can use this glue on a pool toy or piece of pool equipment that spends most of its life in the swimming pool, safe in the knowledge that the bond will endure. As it bonds with plastic and is waterproof it is the perfect solution to that broken part in your toilet cistern that keeps it from flushing. You can use this glue on fabrics, without worrying about having to hand wash the garment for the rest of its existence. Just pop it into the washing machine, and the glue will hold fast!

E6000 is a very versatile invention, and the manufacturers pride themselves on the sheer variety of materials that it will work on. It can glue plastic toys or outdoor furniture, it will bond wood to glass, and even cloth to metal. From gluing crafting beads together for your latest DIY project to hanging decorative pieces and even attaching light fittings to your ceilings, whatever is needed, this glue is a perfect choice because it rarely fails to impress. To give you an idea of just how versatile E6000 adhesive is, we have made a table that shows all the different materials it can and cannot be used with.

| Surface | Can E6000 Be Used on It? |

| Metal | ✔ |

| Wood | ✔ |

| Ceramic | ✔ |

| Fabric | ✔ |

| Rubber | ✔ |

| Vinyl | ✔ |

| Glass | ✔ |

| Plastic | ✔ |

| Styrofoam | ✘ |

| Polystyrene | ✘ |

| Polyethylene | ✘ |

| Polypropylene | ✘ |

Reviews for E6000 Glue

This glue is quite a remarkable product. Giving it a pass in favor of other glues may cause you to miss out on an amazing product. It works on almost every type of material you can imagine, ranging from glass, metal, plastic, wood, and more! Our E6000 glue review and guide on how to use it will demonstrate just how handy this glue is.

There are very few negative reviews of this product. This should instill a great degree of confidence that you can make a range of repairs using E6000 that will endure despite environmental factors. You can use it to fix your lawn furniture, and even the day beds by the pool that are at risk of being splashed by mischievous kids on hot summer days. You might choose E6000 glue to repair that beloved china teapot that you inherited from your great grandmother, or the heirloom that was accidentally smashed during your last relocation. One reviewer has even claimed that E6000 worked on their kayak, while another managed to keep a broken fin on a surfboard from falling off.

If you need more convincing, all you need to do is go online and search for the reviews of this product. The overwhelming majority will be positive. Where you do find that someone has had a bad or disappointing experience, keep in mind that as with all adhesives, there are some procedures, that if not followed, will make even the best adhesive fail. Before you you apply any glue, make sure that both surfaces to be bonded are clean and free of oil, grease, rust, or loose paint. You need the glue to adhere to your material, not whatever is on it.

You will even find reviews where tests have been conducted to determine the strength of E6000 glue in Pounds per Square Inch, PSI. The tensile strength of E6000 has been measured at up to 3200 PSI, which is one of the highest known tensile strengths for an adhesive. When it comes to durability, the shore hardness for E6000 has been measured at up to 80. Meaning that once fully cured, this adhesive is very unlikely to fail.

With all this talk of the glue’s strength, we do feel it is important to include a word of warning. Because it is such a fast-acting adhesive, it dries on skin extremely quickly. So, unless you want to glue your fingers together, we highly recommend you wear protective gear. In particular, a good pair of gloves, an eye mask, and a respiratory mask.

- Exceptionally strong to industrial standards

- Versatile, flexible and adheres to most substrates

- Will not break down or become brittle with temperature extremes

- UV-resistant

- Not water soluble, waterproof

- Works with many different materials

- Extremely high tensile strength

- Extremely high shore hardness

- Flexible once dried

- Not flammable

- Only comes in small amounts, no bulk options

- Intense odors

- Spreading the glue smooth is difficult

- Difficult to remove once dried

Comparing E6000 to Another Reputable Glue Brand

Now that you have read all there is to know about E6000 glue’s strength and multitude of applications, it is a good idea to learn how other glues compare to this one. Reading reviews online is not enough, but you can easily learn in this next section where we will be comparing the similarities and differences between E6000 and adhesives that offer similar outcomes.

E6000 Glue

We don’t want to drone on too much, because we have pretty much covered everything there is to know about E6000 by now. But, we will discuss some of the basic features and components that characterize most adhesives, and how these compare to the formula that makes up E6000.

E6000 is polyurethane-based, making it a hardy product that can withstand weather extremes ranging from humidity, to dry heat, and severe cold. Its bond has been known to survive even thunderous storms where winds can shear things apart. Indoors, E6000 is ideal for fixing mugs, bowls, or plates, because once cured, it is food safe. One potential irritant is the fact that the product only comes in quantities of 4.5Oz. Do not let the small size fool you though, because what it lacks in quantity, it makes up for in tensile strength.

The E6000 adhesive is one of the most popular adhesives on the market today because of its fast drying time and versatility, and the fact that it dries transparently. Its popularity is also due to its wide applicability. This glue can be used on wood and metal, plastic and fabric, vinyl and rubber, to mention a few. However, when it comes down to it, technically speaking, super glue is very similar to E6000 glue, so the comparison is a bit like comparing a Granny Smith Apple with a Pink Lady, they are the same fruit, with only minor variations. There is one main point of difference though: where superglue dries brittle, E6000 has a flexibility that makes it less likely to crack or fail in the long run.

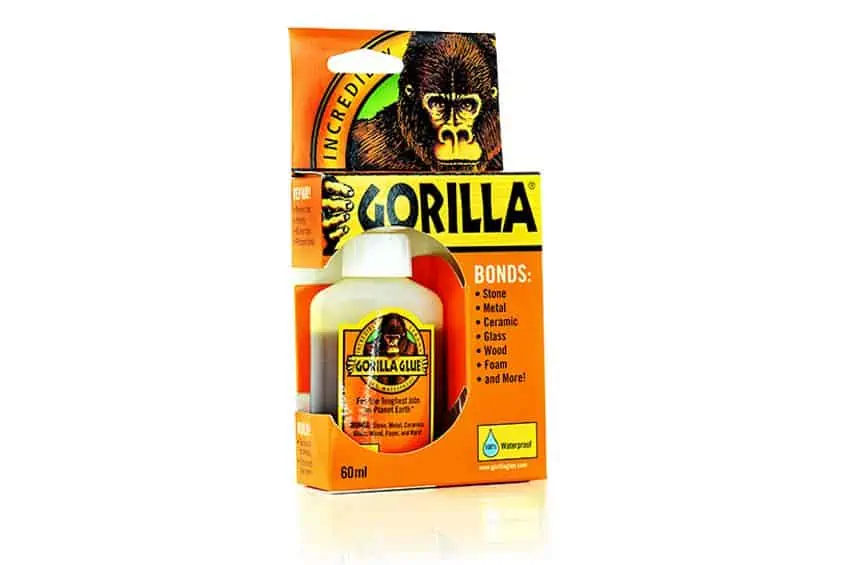

Gorilla Glue

Now that we have set the standard of what to expect from a great adhesive. We can see what the other glue brands have to offer in comparison. The glue that comes closest to E6000 in terms of performance is Gorilla glue. Although Gorilla makes various types of glues for several different projects, their signature adhesive is the most similar to E6000 glue.

The tensile strength of Gorilla Glue has been measured at up to 4250 PSI, which is higher than the E6000 adhesives. While there is no available data of the shore hardness of gorilla glue, one can assume that given its PSI that its shore hardness should also be very high.

In terms of aesthetics, Gorilla glue also dries transparent, so there is no ruining the appearance of our favorite mug, or serving platter. Gorilla glue is also a popular candidate for fixing your crockery sets since it is also food safe. It can withstand being knocked around or dropped accidentally when the glue has dried, and this is possible because of the rubber that is found in the formula, making it shock-resistant. The main difference between E6000 and Gorilla glue is that E6000 works extremely well on plastics and vinyl, whereas Gorilla glue does not. Given how much of what we use nowadays contains plastic, this is a big advantage.

Applying E6000 Glue

It must be about time for you to start wondering how to use E6000 glue, and it is now that we will explain exactly what you need to do. Make sure that you have gathered all the mold and materials needed to complete the job without having to stop to get something that the proficiency of the glue relies on. Working with E6000 is not a long and laborious job, but read these instructions just to make sure you do not make a massive task out of it unnecessarily.

Surface Preparation

The first step in the process of gluing with E6000 is the preparation of your surface. This includes making sure that both pieces you are gluing together are clean and free of any dust particles or oily residue, which will prevent the glue from working as well as it should. It also means that some surfaces like certain plastic will need to be primed with a coating to protect the surface from the glue, and prevent the surface from warping. Make sure you read the instructions of the E6000 glue provided by the manufacturer.

Applying E6000 to a Surface

The way you apply the E6000 glue is the same irrespective of the surface material you are gluing. Thankfully, it is designed with a narrow nozzle, making it easy to get into those small crevices. What is interesting is how the manufacturers have firmly stated that the best way to glue porous surface materials with E6000 glue, is by applying the glue, attaching the items, waiting five minutes for the glue to set, then pulling the items apart again and re-sticking them together again after. That might seem bizarre, but it is what makes the adhesion stronger for that type of material.

Re-sealing the Tube

This step is simple and should be second nature to you. If you do not accurately re-seal the E6000 packaging it might dry out, or even evaporate. This glue has about a year’s shelf life, but you need to make sure you have sealed it properly after every use.

Drying Time

The drying time for E6000 is only five minutes! This is remarkable and extremely useful for those who need a quick fix. The full setting or curing time for E6000 glue is about 24 hours, so if you broke something important, you will not be able to use it for the next 24 hours, which is not that far off from the standard-setting time for most adhesives.

E6000 is an amazing and versatile adhesive, as you can probably tell after reading this article, is likely a very helpful solution for your DIY project! You will now understand more about E6000, its uses, and how to use it properly.

Frequently Asked Questions

Can I Use E6000 for Sealing Food Packaging?

You can use E6000 glue when you are fixing a plate or a mug that will hold coffee or some cereal and milk because the glue is not water-soluble. However, this does not mean that the glue should come in direct contact with food until 24 hours have passed and the glue has properly set.

What Is E6000 Used for?

E6000 is a versatile adhesive that can be used for a variety of projects and can bond just about any material. However, as with all adhesives, it does have some limitations.

How Toxic Is E6000?

It is important when using E6000 adhesive to wear appropriate protective gear like a respiratory mask, an eye mask, gloves, and whatever else you deem necessary to protect your eyes, skin, and lungs. Direct skin contact with E6000 is best avoided.