Best Silicone Mold Kit – Making Your Own Silicone Rubber Molds

This post may contain affiliate links. We may earn a small commission from purchases made through them, at no additional cost to you.

These days, there is an assortment of ready-made silicone molds you can purchase to use for a variety of things. They come in a variety of shapes and sizes, and yet you might not be able to find exactly what you require. Why not use one of the resin mold kits? You can create whatever shape you desire using a resin mold kit.

Table of Contents

What Is Silicone Rubber?

Silicone is a polymer and in itself is a rubber-like material. It contains carbon, hydrogen, oxygen, and silicon. There is an assortment of formulations and it can be found in either a two-part or single polymer. Certain silicone contains fillers, that add to the properties of the silicone while making the product more affordable. Properties of silicone include:

- Non-adhesive properties

- Resistant to tearing and durable

- Low levels of toxicity

- Stable

- Abrasion- and UV-resistant

- Non-reactive

- Amazing electrical insulation properties

- Withstands a range of temperatures (-70 to 570 degrees Fahrenheit, or -56,6 to 229 degrees Celsius)

![]()

As a very versatile product, silicone rubber can be shaped and manufactured with ease and can be used in a variety of ways. For example, it can be used in several automotive applications such as insulators, baking and cooking products, home repair items such as sealants, footwear, and so much more. What we will be focusing on is silicone in mold-making kits. These will form flexible, durable molds that can be utilized to replicate items. Several factors classify silicone, which include the viscosity and how it has been processed. In terms of these elements, silicone is available in three types:

- Solid Silicone Rubber, also referred to as HTV (High-Temperature Vulcanized)

- Liquid Silicone Rubber (LSR)

- Room Temperature Vulcanized (RTV)

![]()

Silicone rubber is primarily utilized in the automotive industry and other industrial applications. Liquid silicone rubber is known for use in injection molding. For encapsulations or molding, and sealants, one would use room temperature vulcanized silicone. Silicone’s hardness is measured using a scale called the Shore A hardness scale. The rubber’s firmness can be anything from hard to soft. The measurement of Shore A gives a number between 10 to 100. Higher numbers of measurements indicate a harder silicone.

| Different Types of Silicone | Hardness Scale |

| Solid Silicone Rubber | Levels ranging from 60 to 90 Shore A (High hardness) |

| Liquid Silicone Rubber | Levels ranging from 10 to 80 Shore A (very soft to hard) |

| Room Temperature Vulcanized | Levels ranging from 15 to 40 Shore A (very soft to medium soft) |

When working with any form of silicone resin mold kit, you would be using the RTV (room temperature vulcanized) silicone. A silicone resin mold kit is available in either a single or two-part product. The two-component product consists of a catalyst and a base, the catalyst will begin the curing process.

The majority of silicone mold-making kits are two-part components. You will require hardly any preparation when working with silicone molds when casting resin or other materials. You can use ordinary vegetable cooking oils or a mold releasing agent to ensure the item will be released from the mold with ease. It is relatively easy to remove an item from a silicone mold as they are very flexible.

![]()

Buyer’s Guide for Silicone Mold Kits

At the end of the day, it is easier to just buy a pre-made silicone mold. However, if you are hoping to purchase a silicone mold-making kit, there are certain aspects you will need to take into consideration. Certain resin mold kit products can be quite pricey, so you want to be sure you are buying the correct one.

![]()

Silicone Drawbacks

Are you certain you require a silicone mold? Silicone has its benefits but it also presents certain limitations. To start with latex and other organic rubber products are more affordable than silicone. While silicone is a flexible substance, it may tear under pressure. Not all silicone products are made in line with high standards, so you want to be certain you are buying your silicone from a reputable and well-known supplier.

![]()

The Purpose of the Silicone Mold

Silicone molds are available for an assortment of uses and purposes, what is yours? Are you looking for a baking mold or a mold for chocolate? If so, you will require a substance that is resistant to heat and, more importantly, has to be food-safe! You will require a substance like epoxy resin to be chemical resistant. If you are unsure if the product will suit your requirements, you can always consult the manufacturer’s instructions.

![]()

Silicone Viscosity and Hardness

Your silicone mold kit needs to be odorless, clear, and colorless to be considered high-quality. You want to ensure that your liquid silicone is not too thick or too thin. You will also need to think about your blank; is it heavy or large, and are there lots of details? To retain and remove finer details, you will need to determine the ideal silicone hardness.

![]()

A lot of the silicone mold kits are available in liquid form, but there are other options to look at. Other options include silicone putty or plastique, which is easy to use. This type of silicone is made up of two parts, and once mixed together, you can mold it into shape for about 20 minutes before the curing begins. Silicone putty is perfect for use for smaller projects and is also food safe.

The Quality of Silicone

The durability of a high-quality silicone mold product is much better than a low-quality, cheap product. If you take care of it a high-quality silicone mold can last as long as seven years. You want a silicone mold that can withstand wear and tear and is both sturdy and flexible.

Best Silicone Mold Kit Products

Which Silicone mold kit to use all depends on what your project’s requirements are, to determine which is the best kit for your needs. That being said we have put together a list of three different mold-making kits from putty form to liquid form. You can use these molds to make practically anything from soap, resin, food, and so much more.

![]()

Best Putty Mold-Making Kit: ALUMILITE Amazing Mold Putty Kit

This kit can be used to form a mold for a variety of materials like wax, soap, food, resin, and much more. The silicone putty is safe to use and simple to handle. What makes this putty particularly great is that you will not require any additional tools such as sticks and extra measuring cups. This particular kit has FDA approval and is completely food safe.

It is a quick process to use this kit, taking less than half an hour. Combine equal parts of the two forms of putty. You then use this putty to form your mold. It will take about 20 minutes for the mold to cure, and you will then be left with a flexible, rubber mold that has great durability.

- Hand-mixed putty makes flexible and detailed rubber molds

- Create molds for casting resin, food, soap, wax, clay and more

- Produces a reusable mold in 25 minutes without equipment

- Suitable for various applications

- Simple to use

- Well-priced

- Food grade

- Purchasing large quantities of this product can become quite pricey

- Not ideal for larger molds

- There are many complaints regarding the packaging

Best Liquid Silicone Resin Mold Kit: LET’S RESIN Silicone Mold Kit

This kit is made up of silicone which has no odor and is non-toxic. Once cured the silicone is soft, clear, and flexible. This resin mold kit is easy to use and comes in two components. The two parts need to be combined with a 1:1 ratio. As long as you are working at room temperature you will have five minutes of working time.

As you work you may notice a few bubbles, but you should not worry about these as they will disappear after roughly two hours. You will not have to vacuum degas. The silicone will be fully cured in roughly 12 hours; however, this curing time could be impacted by the surrounding temperatures, the mold’s size, and the thickness of the mold. If after a certain amount of time the mold still feels tacky to the touch, simply allow it a bit more time to cure.

This is the perfect resin mold kit for beginners, as you do not require any experience or special skills. It is also simple to clean up, all you will need is a bit of soap and water, or you can use a little rubbing alcohol. This kit can be used for an assortment of applications from candle molds, to creating resin molds. Sadly, this particular kit is not food-safe.

- Premium translucent liquid mold-making silicone

- Easy 1:1 mixing and pouring with 5 minutes working time

- Bubble-free, non-toxic, and odorless

- Easy to use

- Non-toxic

- Bubble free

- Pourable

- Fast drying and curing times

- Ideal for beginners

- Not food safe

- Can only be bought in limited volumes

Best Easy to Use Silicone Mold Kit: SMOOTH-ON Silicone Mold-Making Kit

This is a simple to use mold-making kits that require a 1:1 ratio when combining the parts. The silicone will cure medium to soft with a Shore A Hardness measurement of 30. This means you are left with silicone that is tough, while still being flexible. You have roughly half an hour of working time with the product taking six hours to cure completely. The pouring liquid offers low viscosity and can be utilized for both two-piece and single block molds. You will not need to vacuum degas. This product can be used for arts and crafts projects, but can also be used by professionals to create sculptures and other forms of industrial applications.

- Soft to medium range rubber for easy demolding

- Cures at room temperature with minimal shrinkage

- Ideal for simple block molds, no vacuum degassing required

- Ideal for professionals and beginners

- Simple to work with thanks to the low viscosity

- Easy to mix and pour

- Pricey

- Can be quite messy to work with

- Air bubbles may cause problems

How to Use a Silicone Mold Kit

The majority of silicone mold kits are made up of part A and part B. You will need to combine the two parts, usually with a 1:1 ratio in terms of volume. Then press or pour around the piece you wish to make the mold of. Curing time and working time may differ, so you will also need to consult each product’s directions.

There are also brush-on molds available, that provide the mold with additional flexibility, and useless silicone than pouring. However, you will need more patience when working with brush-on molds as you will have to apply several layers. Brush-on molds are usually utilized more for complex shapes that could prove hard to pour.

![]()

Making a One-Piece Mold

There are many benefits to a one-piece mold, making it a very popular option. One-piece molds are so simple to make, and you will be able to do it with ease. You can also reduce the seam lines, which has a less visual impact on the end product. To begin with, you will need to pick the item you are looking to mold and then make or find a container or a box to place the item in so you can pour the silicone over it. The size of the container depends on the particular item you are looking to form a mold of. A potential small container would be a Styrofoam cup.

Place the item you are looking to form into the container. To ensure that it does not float around use a small amount of hot glue to glue it down. You may need to apply some super seal and a mold releasing agent, depending on your item.

The majority of mold-making kits will not require the use of vacuum degassing, so you can just start pouring into the cup. Pour into one spot and allow the liquid to move over the item by itself. Allow the silicone to time to cure, once cured you can then demold it. You will be left with a flexible silicone mold that is ready to be used for casting.

Making a Two-Piece Mold

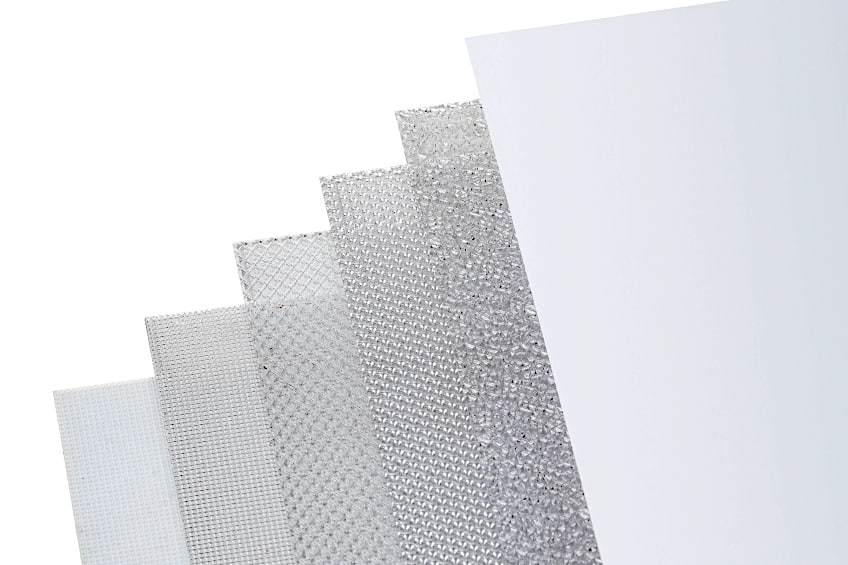

This is the ideal method to use if you are looking to form a three-dimensional mold and the end mold product comes in two pieces, split along a horizontal line, and when casting an item, it will fit together. A sphere is a great example. To begin with, you will need to make your mold container. This is the item that needs to hold your silicone and the item until the silicone has hardened. A great material to use to create your mold box is acrylic strips or sheeting, thanks to it being transparent. You will of course have to lightly glue the sides.

When your mold box has been built, you will need to place some clay at the bottom. You then want to partially embed your mold item into the clay. You want to ensure that the clay is even and smooth around the item, so you might need to flatten the clay. You should have already decided the seam line of your model, and this should be how far your item needs to be embedded into the clay.

Take several domed cap nuts, and place them flat side down around the model, in the clay. These domed cap nuts will form your registration or model key that will assist you in keeping your mold in place whilst casting. Next, you can combine the two-part components of your silicone mold-making kit and then pour the mixture over the exposed pieces of your model. To combine the two-part components, you should take equal parts and mix thoroughly. Once the components have been mixed you can begin pouring into just one area and allow the liquid to spread on its own until it is about half an inch above the model piece. You will then need to allow sufficient time for the mixture to cure.

![]()

When it has cured you can then take apart the mold box, and remove the nuts and clay. You can then trim and flash and once you are certain all the clay has been removed you can then reassemble the box around the silicone and mold once again. The silicone that has already cured will be sitting at the bottom. You will need to spray some mold-release across the item’s surface. You want to be certain you have applied an even layer. In certain cases, the molded item itself can form the spout when you do your casting.

![]()

Alternatively, you can form your spout using a little clay. Should you choose to do this option you can form a funnel shape from the clay and put it onto the sphere so that it extends from the hardened silicone. Then follow the same process as previously when using the silicone mixture. You want to ensure that the clay funnel you have added, slightly extends. Allow the silicone to cure and then de-mold your molded item. Remove the clay funnel and mold box and trim away any flashing. Carefully peel back the silicone rubber and you will be left with a two-piece silicone mold.

Steps for Making Your Own Silicone Molds

If you only need to make molds of small pieces and you are not looking to spend a fortune, you might want to think about creating your mold from silicone that can be easily bought from your local hardware store. Ensure that the product is labeled silicone I not II and is defiantly silicone, you also want to ensure it is not the fast-setting kind of silicone. We recommend you work in a space that has adequate ventilation when making your silicone mold.

Combining Your Ingredients

Take a large bowl, (big enough to place your entire hand into) with lukewarm water. Next, you can add a little liquid soap, to ensure it is clear. The soap is a catalyst, speeding up the curing process of the silicone. You such use a ratio of 10 parts water to one part soap. You will either get a syringe or a caulk gun with your silicone caulk that you can use to squeeze it out. Squeeze a portion of the silicone into the water and soap, you could even use the whole tube.

![]()

Kneading the Silicone

Place your hands into the bowl carefully, and bring all the silicone together into a ball. You can then begin kneading it until the silicone no longer feels tacky or sticky. This should take you roughly five minutes. When kneading the silicone, you may want to wear gloves. Once kneaded together you can remove the silicone from the bowl and you can continue kneading it out of the bowl until it feels less malleable.

![]()

Use Your Chosen Item to Create a Mold

You can either create a flat dish shape with the silicone, that you can then press your item into. This is the best option if you are working with a flat mold item that has patterns. Ensure you press the item firmly ensuring that the whole surface has been covered with silicone. Allow it time to harden. Remove the molded item and you will be left with a mold that is a replica of your chosen piece This is then referred to as a negative mold.

Another option is to apply a thick layer of silicone to a three-dimensional item. You want to ensure that there is roughly half an inch of silicone around the item. You want to ensure a portion of the item is exposed to allow it to come out easily once the silicone has cured.

Creating Molds Using Other Methods

There are a variety of other methods, from using silicone and cornstarch, or silicone and turpentine, both adding a small amount of acrylic paint to give it a little color. You will need to wear gloves when using either of these methods, and the materials could potentially give off an odor when you are working with them. The above-mentioned method is a lot safer, easier to do, and is a great option if you wish to get the children involved.

Tips for Making the Best Silicone Molds

Creating a mold is a process, so you do not want to waste your time, make mistakes, and have to start again. We highly suggest you sign up for a workshop to get some practical experience if you want to take making molds seriously. However, what follows are a handful of tips and tricks that can assist you if you are simply creating an art and craft project at home.

- Ensure you have the right size mold box so that none of the silicone product goes to waste.

- You can use a transparent plastic cup as a simple mold container if you are working with a small one-piece mold. Other food containers make great mold containers as well.

- Take care in what item you use as the template for the mold, as the surface of the item will reflect on the mold. You cannot use a template item with a rough surface and expect to produce a smooth mold.

- To ensure you do not experience any demolding problems, remember to apply a mold release spray, particularly if the item you are working with is porous, such as wood.

- If you are using a silicone item as your template, you will have to use mold release as silicone will stick to silicone.

- Your thickness and temperature will impact the curing or hardening process. If it feels tacky, rather leave it to cure a little bit longer.

- When combining the two components from a mold-making kit, always ensure that you have mixed them thoroughly before you apply or pour them.

- Always consult the instructions, and ensure you are mixing the right amounts.

- You should ensure that you are working at room temperature, the curing time will take considerably longer if the temperatures are cooler.

- Ensure you use the right release agent and sealer for silicone mold-making, and apply as per the instructions.

The easiest way to create your mold is to make use of a silicone mold kit. You will just need to follow a handful of simple steps, and you will be able to create a stunning, unique mold that can be used over and over again. We hope to have inspired you to create the best silicone mold and get started on this exciting journey!

Frequently Asked Questions

Can a Cardboard Box Be Used as a Mold Box for Silicone?

It all depends on the type of box, if it is a sturdy box that will not allow the silicone to leak out, then yes. There are ready-made mold boxes available to purchase on the market, but it is also quite simple to create your own. A lot of DIY-ers choose to use acrylic strips or sheets thanks to their transparency and because it is a sturdy material.

How Durable Is a Silicone Mold?

It is all dependent on the quality of silicone you have selected to use and how well you made the mold. As long as you take good care of it, a silicone mold should last several years. To enhance a mold’s durability and maintain its condition we recommend cleaning it after each use.

Are Silicone Mold Kits Toxic?

The majority of silicone mold-making kits are non-toxic and odorless, making them perfectly safe. However, to determine if they are food safe, we would recommend you check the product label.

Why Is My Silicone Mold Hard?

If you use simple caulk silicone that is of poor quality, your mold might end up being too hard. In addition, if you have made the mistake of kneading the silicone too much, it will become harder than intended. The packaging of the silicone should advise that it is 100% silicone and should only be utilized for medium to small-sized molds.